The traditional “push” model, based on forecasts and best guesses, is being replaced by a “pull” dynamic, where procurement, production, and distribution are driven by actual customer demand. This change is significant and allows for a more efficient approach to fashion production, with lower capital investment, smaller inventories, and increased flexibility.

What Is On-demand Clothing Manufacturing?

At its core, on-demand or made-to-order manufacturing in fashion is about creating clothing only after an order has been placed. This concept stands in stark contrast to the traditional model of mass production, where garments are manufactured in bulk and stored in warehouses until they’re sold.

Instead, on-demand fashion manufacturing leverages advanced technology and innovative supply chain strategies to create garments in response to consumer demand, reducing waste, overproduction, and inefficiencies along the way.

Initially, the shift to on-demand manufacturing and production came in response to trends and customers’ increased desire for customized clothing pieces. Gone are the days when fashion designers, retailers, or editors were the single ones deciding on the next fashion trend. Today, trends are most often set by the fashion consumers themselves.

Yet, the benefits of this system are manifold and go beyond satisfying clothing buyers.

Lower capital investment and more efficient inventory management are among the advantages the on-demand manufacturing approach brings to clothing and fashion brands.

The Multiple Benefits of On-demand Manufacturing

1. Satisfy Customers With Customized Clothing

One of the most compelling aspects of on-demand manufacturing is its ability to offer customization and personalization options to consumers, enhancing customer satisfaction and loyalty.

With the power of automation and data analytics, start-ups and mass-market players are adopting agile made-to-order production cycles. This shift enables a rapid response to trends and consumer demands, resulting in just-in-time production, reduced overstock, and an emphasis on small-batch production cycles.

For example, with advancements in technology such as 3D printing and digital pattern-making, brands can now create made-to-order garments tailored to individual preferences and specifications.

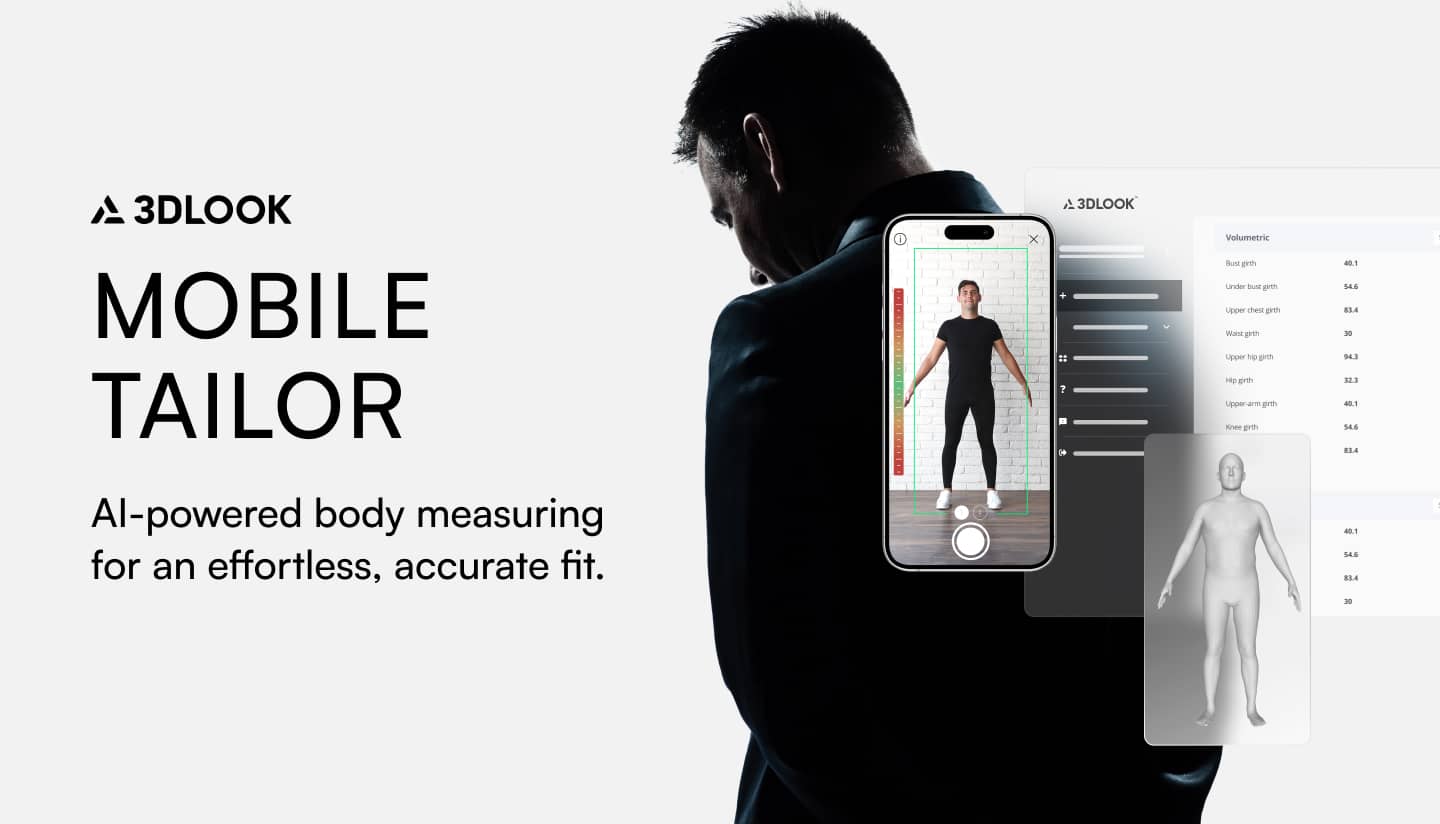

Solutions like 3DLOOK’s Mobile Tailor offer significant advantages to brands and retailers specializing in custom apparel. Leveraging precise 3D body models through body scanning technology, this solution enables them to craft and personalize garments with impeccable fit without the necessity of conducting in-person measurements or fittings with models. Essentially, Mobile Tailor empowers brands and retailers to effortlessly obtain accurate body measurements from their clientele remotely.

Nike, the sportswear giant, has embraced on-demand manufacturing through its Nike By You program, which allows customers to customize and personalize their sneakers online. Leveraging digital design tools and advanced manufacturing technologies, Nike produces custom sneakers on demand, reducing lead times and meeting consumer demand for unique, personalized products.

Another example is the Louis Vuitton clothing brand with its Mon Monogram program that allows customers to have their initials placed on the products they purchase.

This degree of personalization caters to today’s consumer, who cherishes uniqueness and diminishes the probability of returns. Research indicates that tailored products lead to fewer returns as they better match customer expectations.

2. Address Fashion Industry’s Waste and Ethical Production Problems

Conventional fashion manufacturing frequently results in overproduction, leaving approximately 30% of garments unsold. On-demand fashion manufacturing reduces this waste by producing garments only after an order is placed, potentially saving billions of garments from ending up in landfills.

Additionally, it allows designers to allocate more resources to their designs. Producing fashion pieces only on demand slows down the pace, mitigating time constraints and minimizing the risk associated with production in unregulated facilities. This “slow” approach meets ethical standards and expedites the delivery of ethically produced clothing garments.

On-demand manufacturing can also support ethical labor practices by promoting smaller-scale production, which allows for better oversight of working conditions and fair wages for workers.

Brands like Everlane have embraced transparent supply chains and ethical manufacturing practices. While they may not operate on a strict on-demand model, their commitment to transparency and fair labor practices sets an example for the industry. When consumers know where and how their products are made, they can make more informed purchasing decisions that align with their ethical values.

3. Reduce Inventories

Another key benefit of on-demand fashion manufacturing is its potential to decentralize production and eliminate excess inventory.

Creating items exclusively in response to customer orders leads to a more efficient and streamlined production process, also positively impacting cash flow.

One prominent example is the Zara brand. The company placed its manufacturing close to distribution centers enabling its capacity to ship products frequently and in smaller batches. This way the company evades the risk of underperforming styles while minimizing excess inventory.

Currently, Zara’s strategy is to design and manufacture around half of their production line in the middle of the season. Their strategy aligns with Zara’s success in navigating today’s dynamic business landscape, granting them the responsiveness necessary to adapt to economic and technological shifts.

4. Support Sustainable Approaches

In an era where sustainability is increasingly prioritized by consumers, on-demand manufacturing emerges as a viable solution to address the fashion industry’s environmental and social challenges.

The latest statistics reveal that textile waste is bound to increase by about 60% between 2015 and 2030. On-demand production can lead to a significant reduction in fabric waste.

By producing garments on an as-needed basis, brands can significantly reduce waste, carbon emissions, and water consumption associated with traditional manufacturing processes. Additionally, fashion companies reduce their carbon footprint by eliminating the need for long-distance shipping and warehousing of excess inventory. Sustainable fashion brands choose to produce clothing closer to the point of sale and ship directly to customers, thus lowering transportation emissions and overall environmental impact.

On-demand manufacturing supports the use of sustainable materials and responsible sourcing, as it allows for more thoughtful and deliberate production processes. For example, Thread International is a sustainable fashion company that uses on-demand manufacturing to produce its line of apparel made from recycled materials.

Another example is MADE Outdoor, an apparel company that fosters sustainability and inclusivity. However, the brand encountered initial hurdles with remakes and returns, mainly from inaccurate sizing during its launch.

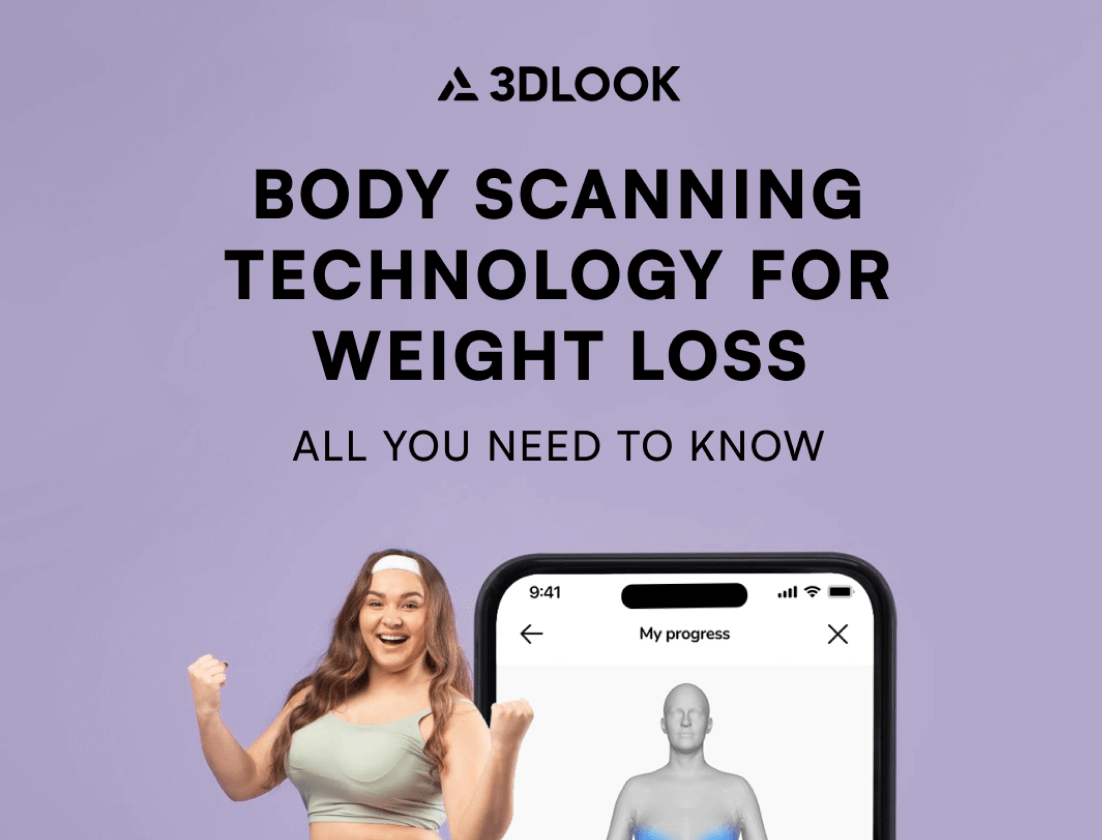

MADE integrated customer body data obtained through Mobile Tailor’s 3D scanning to refine pattern fits and solve the issue with ill-fit sizes. 3DLOOK’s technology guarantees that garments are tailored precisely to the customer’s measurements. With just two smartphone photos from the customer, the solution generates approximately 70 points of measurement, eliminating the need for a measuring tape.

By leveraging 3DLOOK’s digital body scanning solution, MADE was able to offer more personalized fits from the outset and ultimately achieve on-demand apparel manufacturing at scale. Consequently, MADE Outdoor has significantly enhanced production efficiency and customer satisfaction.

5. Achieve Supply Chain Transparency

On-demand manufacturing fosters supply chain transparency by providing real-time visibility into the production process.

Advanced software and AI can predict trends and optimize production, ensuring that resources are used efficiently and the products align with consumer desires. This caters to the market’s demand for personalization and fosters a culture of responsible consumption.

By digitizing production workflows and tracking orders from raw materials to finished products, brands can ensure ethical sourcing practices and monitor production conditions more effectively.

Loomia, a technology company, develops smart textiles embedded with sensors that track a garment’s entire lifecycle, from production to consumer use. By leveraging blockchain technology, Loomia enables brands to verify the authenticity and sustainability of their products, enhancing supply chain transparency and accountability.

6. Save costs

Made-to-order clothing manufacturing or just-in-time production minimizes excess inventory, reduces storage costs, and eliminates the need for large production runs, resulting in significant cost savings for fashion companies.

Brands don’t have to commit resources to create and store hundreds of garments upfront. This reduction in upfront costs can free up capital for other areas of the business, like marketing and product development.

Overall, fashion companies can produce goods more efficiently, with lower setup costs, reduced labor expenses, and optimized use of materials. Additionally, by leveraging digital technologies and automation, companies can further reduce production costs and increase operational efficiency.

For instance, fashion companies can adjust production volumes in real-time based on demand fluctuations, seasonal trends, or market conditions, avoiding the costs associated with excess capacity or underutilized production facilities.

7. Gain Speed to Market

The ability to quickly bring products to market is a significant competitive advantage. On-demand fashion manufacturing is emerging as a key player in this aspect, offering a nimble approach to production that aligns closely with consumer demand and reduces time-to-market.

It enables fashion companies to bring products to market much faster than traditional manufacturing methods, where the industry mostly operates on a seasonal model, with designers and buyers predicting trends months in advance.

This approach often led to overproduction, waste, and missed opportunities since predictions didn’t always align with actual consumer behavior.

On-demand manufacturing turns this model on its head, producing items only when there is a confirmed demand. Brands can significantly reduce lead times and respond quickly to emerging trends and consumer preferences.

The McKinsey report on fashion and on-demand production highlights the benefits of this approach, noting that automation and data analytics have enabled a new breed of start-ups to adopt agile made-to-order production cycles. This shift allows for a more responsive approach to consumer trends, which are increasingly influenced by social media rather than traditional retail forecasts.

8. Promote Quality Over Quantity

Made-to-order clothing manufacturing aligns with the principles of slow fashion, which emphasize quality over quantity, ethical production practices, and long-lasting garments. By promoting a more thoughtful and sustainable approach to consumption, on-demand manufacturing encourages consumers to invest in high-quality, durable clothing that lasts longer and reduces the need for frequent replacements.

The primary allure of on-demand manufacturing lies in its commitment to quality. Designers and manufacturers focus on producing smaller batches, meaning they can pay closer attention to detail, ensuring each part meets stringent quality standards. This method allows for greater flexibility in responding to customer feedback and making improvements. The result is often a product that exceeds customer expectations.

One example is Printful, a print-on-demand and dropshipping company that provides custom printing and fulfillment services for clothing brands. The company helps fashion brands launch new products with minimal upfront costs and inventory risk, reducing the barriers to entry for emerging designers and entrepreneurs.

Yet, on-demand manufacturing doesn’t entirely dismiss the importance of quantity. The goal is to find a balance where clothing manufacturers can produce enough to meet demand without compromising quality. This balance is crucial for long-term sustainability and growth, allowing manufacturers to stay competitive and responsive to market needs.

Technologies Fashion Brands Adopt to Support the On-demand Production Model

With the shift towards on-demand production models, fashion brands are increasingly turning to innovative technologies to streamline their production processes and offer customers more tailored experiences.

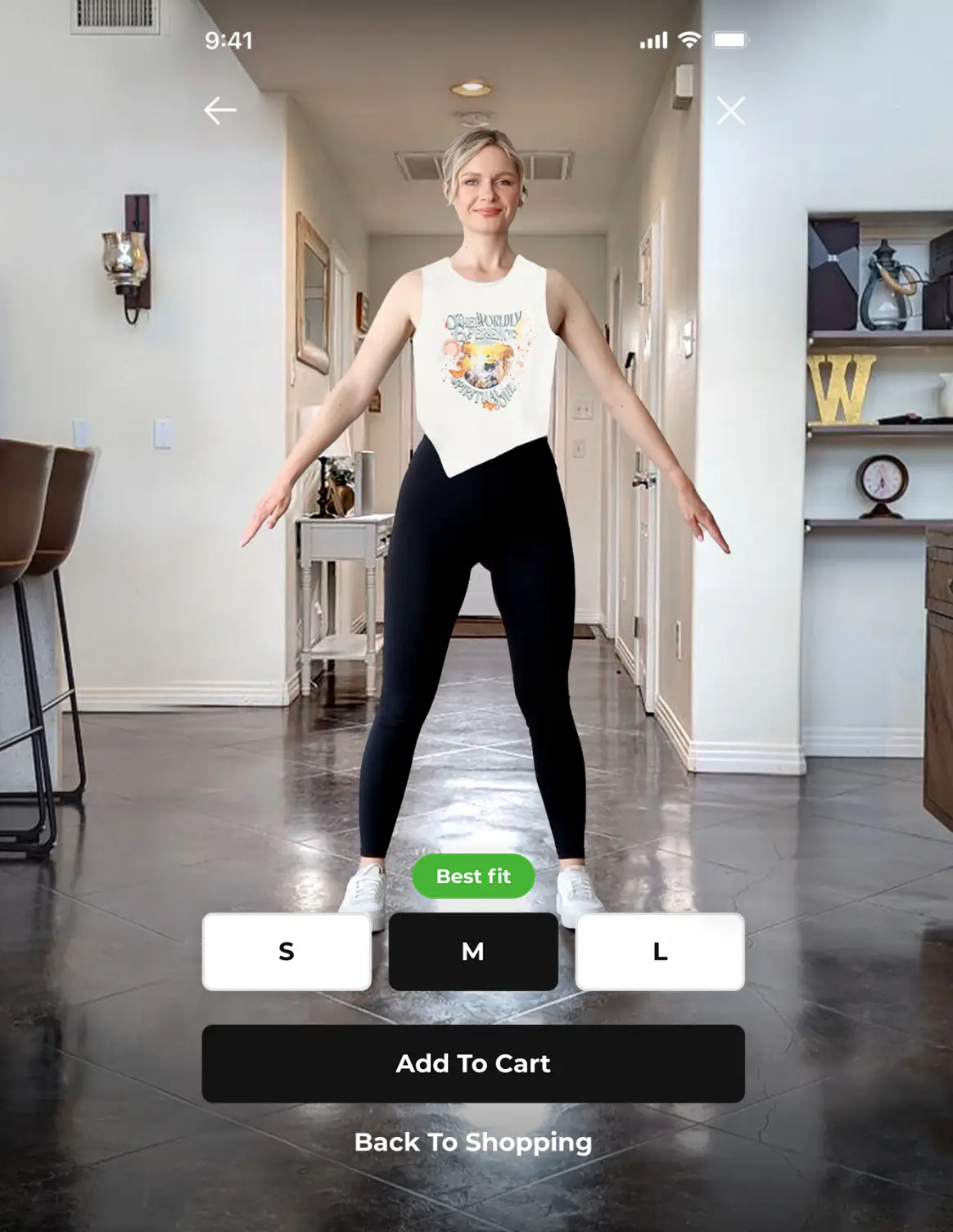

One of the key challenges in on-demand production is ensuring accurate sizing and fit for each customer. Many fashion brands are leveraging AI body scanning technology to address this situation. This technology allows brands to capture precise measurements of customers’ bodies, enabling them to create customized garments that fit perfectly.

Additionally, digital printing and fabrication technologies offer fashion brands greater flexibility and customization in their production processes. Brands can create unique patterns and designs on-demand, eliminating the need for large minimum order quantities and reducing waste. Similarly, digital fabrication technologies, like 3D printing, enable brands to produce complex and customized garments with precision and efficiency.

Adidas, for example, has experimented with 3D-printed footwear, offering customers personalized shoes tailored to their individual preferences.

There are also many companies helping brands to rapidly react to real-time customer demand, reduce waste, and promote domestic manufacturing. For instance, Apliiq offers print-on-demand services for fashion and lifestyle on-demand clothing manufacturing brands in the USA.

Fashion brands also leverage 3D weaving technology to create custom jeans clothing pieces. For instance, Unspun has developed its Vega 3D-weaving tech, which weaves yarn quickly and directly into clothing. They create accurate 3D models through a quick and non-invasive scan that customers can make with their smartphone. This technology ensures a perfect fit, reduces waste, and enhances size inclusivity.

Final Thoughts

More than just a trend, on-demand manufacturing is a necessary step to a more responsible and adaptable fashion industry.

Embracing technology, customization, and ethical practices, brands harness the power of on-demand manufacturing to create a more resilient and responsible fashion ecosystem. As consumer demand for transparency, authenticity, and sustainability continues to grow, the on-demand manufacturing model may become the standard, heralding a new era of economic and environmental responsibility in fashion.

Additionally, with the ever-growing tech developments, we can expect to see even more brands adopting this model, leading to a future where fashion is stylish, sustainable, and consumer-centric.

At 3DLOOK, we’re committed to continuing our mission of supporting sustainable fashion design and production practices. Specifically, Mobile Tailor’s approach to acquiring accurate body measurements through 3D body scanning enhances inventory management and minimizes material waste.

If you’re interested to know more about how fashion brands leverage the latest technology in their on-demand manufacturing models, you can check out this insightful webinar.