Leveraging 3D scanning tech drastically transforms how apparel businesses operate. It boosts efficiency in the apparel market and changes how we shop for clothes. It’s an effective way to maximize customer satisfaction while minimizing inventory costs, returns, and waste. Deploying this technology will give the clothing industry the data needed to design better-fitting apparel and satisfy the range of diverse body shapes to create a more inclusive fashion industry. The ultimate success of 3D body scanning will depend on consumer acceptance and adoption and the technology’s potential to become accessible.

The impact of 3D body scanning on the fashion industry

The main use of 3D body scanning technology in the fashion industry is driving customized sizing and fit and on-demand manufacturing models. The technology can involve advanced sensors, lidar technology, AI, and 3D technologies to create digital representations of an individual’s body shape and size.

Unlike traditional methods of measurement, which rely on manual techniques prone to errors, 3D body scanning offers a precise and efficient solution for capturing accurate body measurements. Thanks to advancements in AI and 3D, a perfect-fitting dress for anybody is now just a 3D body scan away.

3D scanning aids in the creation of tailored garments that guarantee a perfect fit, making it user-friendly technology with vast benefits for brands, manufacturers, and consumers. Implementing mobile body scanning technologies positively impacts fashion companies’ production and supply chain making them more efficient and less wasteful.

The technology can effectively reduce the rate of returns, a common issue with online shopping. This, in turn, decreases waste and carbon emissions associated with transporting and disposing of returned goods. Moreover, the ability to create custom-fit clothing on demand can reduce overproduction, one of the fashion industry’s most critical environmental issues. According to the latest UN Environment Programme report, the clothing industry accounts for a staggering 2-8% of the world’s total greenhouse gas emissions, releasing more greenhouse gases than all international flights and shipping combined.

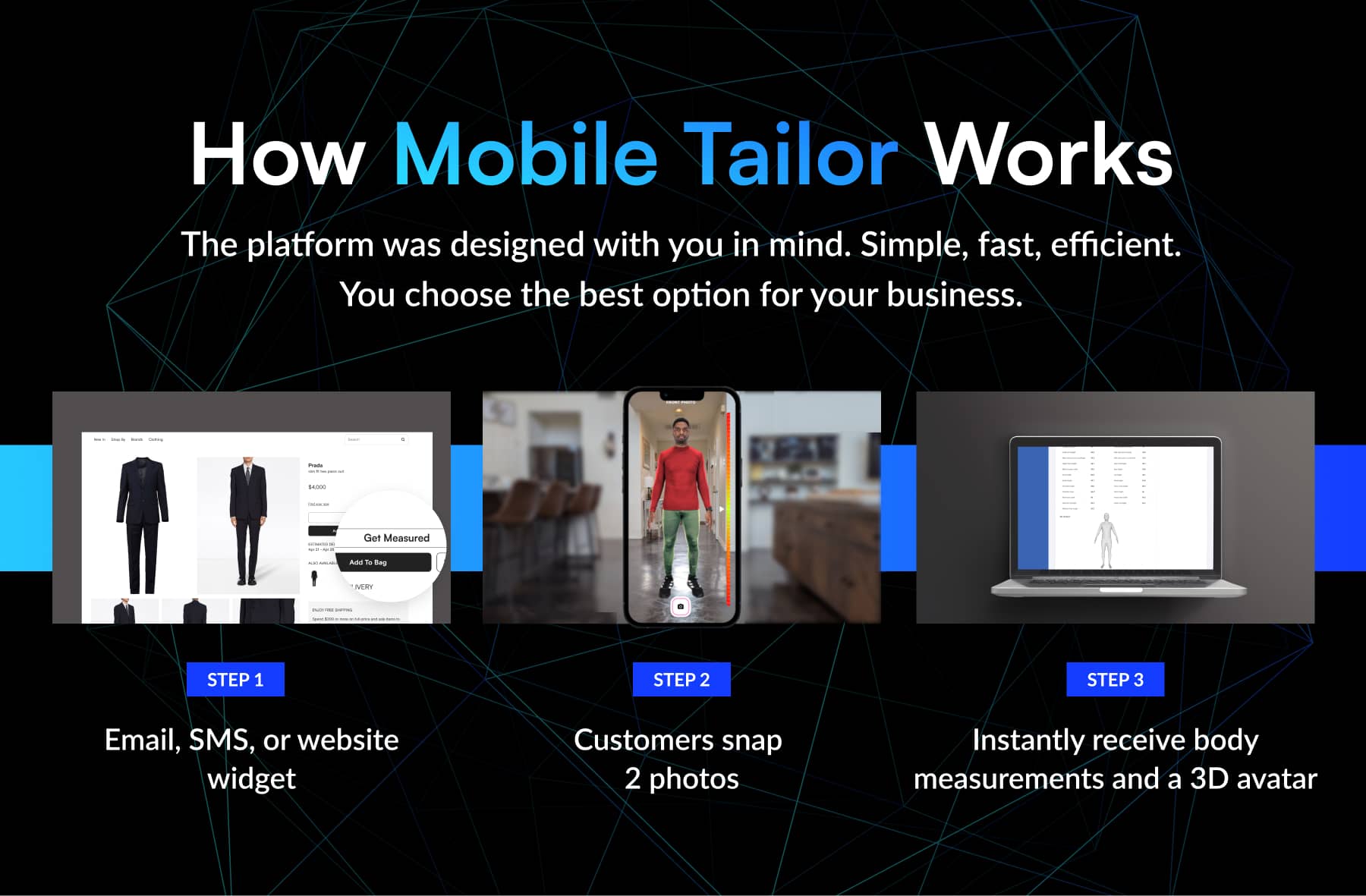

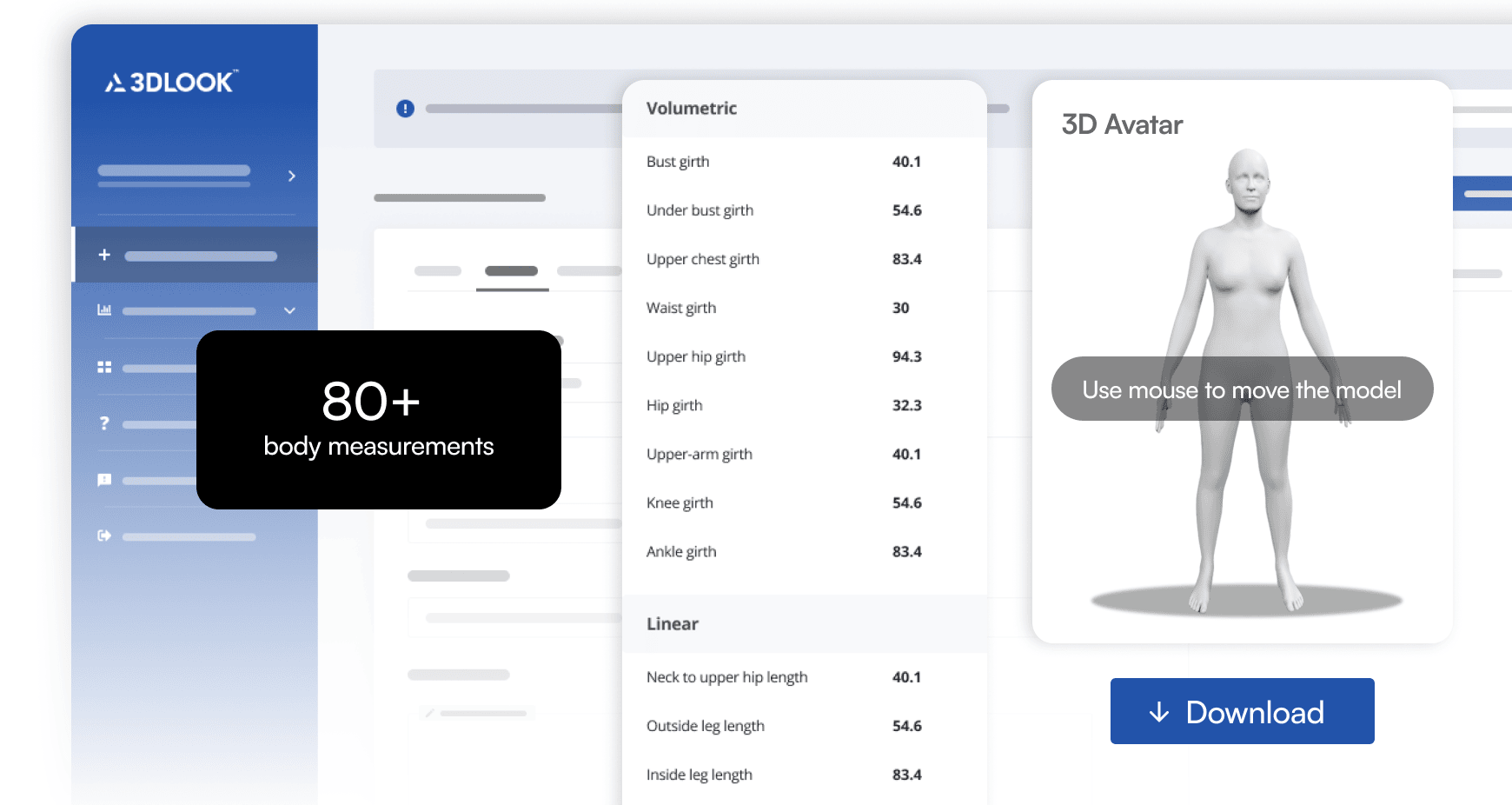

For shoppers, 3D body scanning technology enables the creation of clothes that not only offer an exceptional fit but also accommodate individual style and preferences. Fashion businesses can use a 3D body scanning solution like 3DLOOK’s Mobile Tailor to capture body measurements remotely, without any physical contact. With just two photos of the customer, Mobile Tailor generates more than 85 measurement points of the human body in under a minute, providing a seamless and efficient measurement process.

How accurate is the data from 3D body scanning technologies?

3D body scanning is a scientifically validated technique used to assess body composition. Widely regarded as the gold standard in the fitness community, body scanning is hailed for its exceptional accuracy, boasting a margin error below 2%.

Unlike conventional weight scales, 3D body scanners provide detailed insights, enhancing accuracy by about 5 times better. 3DLOOK’s technology, for instance, analyzes customer photos to create precise 3D body models, capturing over 85 distinct measurements. This process generates over 100 critical data points of the human body, including body shapes, a critical data point for matching clothing to consumers.

3DLOOK’s mobile body scanning technology, trained on datasets of people in tight clothing, offers a quick, simple user experience without requiring consumers to undress.

Applications of body scanning technology in apparel

Increased efficiency in production and supply chain

The adoption of 3D body scanning technology profoundly impacts production and supply chain management within the fashion industry. With streamlined manufacturing processes enabled by digital body data, body scanning technology for apparel enhances operational efficiency and reduces time-to-market for fashion products being manufactured on demand.

Additionally, accurate measurements obtained through body scanning significantly reduce returns and exchanges due to ill-fitting garments, leading to cost savings for brands and retailers. Mobile Tailor significantly streamlines the uniform sector by replacing time-consuming and error-prone manual measurements with efficient digital processes, reducing returns and cutting costs associated with measuring events.

For instance, American Security & Investigations (ASI) reduced their cost savings by 24% by using 3DLOOK’s Mobile Tailor to solve the sizing challenges in employee uniforms.

More innovation and creativity for fashion designers

3D body scanning technology fuels innovation in fashion design, freeing designers from traditional sizing to explore unique shapes and silhouettes.

Fashion designers can now use digital fabric simulation to see how various materials drape on a 3D model from a body scan, allowing experimentation without physical prototypes. This approach streamlines the design process and significantly reduces waste by minimizing the need for physical samples.

Made Outdoor combines 3D scanning with innovative customization technology, offering users unparalleled personalization and fit, while driving a size-free, zero-inventory, and ultra-sustainable business model.

Promoting accessibility and inclusivity

Body shapes vary with age, lifestyle, and geographic location. Research conducted among American women discovered that the average waist size differs among ethnicities, for white women, Hispanics, and black women.

The apparel industry’s focus on mass production often neglects diverse body types, leading to fitting challenges like garments that may fit at the shoulders but not the waist. Numerous surveys have indicated that nearly 50 percent of women struggle to find well-fitting apparel under this standard sizing system. Manufacturers and retailers lack accurate body measurements of individual consumers, hindering the creation of perfectly fitting garments.

A key advantage of 3D body scanning in fashion is its contribution to enhancing accessibility and inclusivity. This technology allows for precise mapping of consumers’ diverse body types, enabling brands to serve a wider audience with tailored clothing options. Furthermore, 3D body scanning offers the potential to revolutionize clothing for individuals with disabilities by offering customized solutions that meet their unique needs and preferences, positioning brands as leaders in adaptive fashion innovation.

Consumer benefits of body scanning technology

Precision in sizing

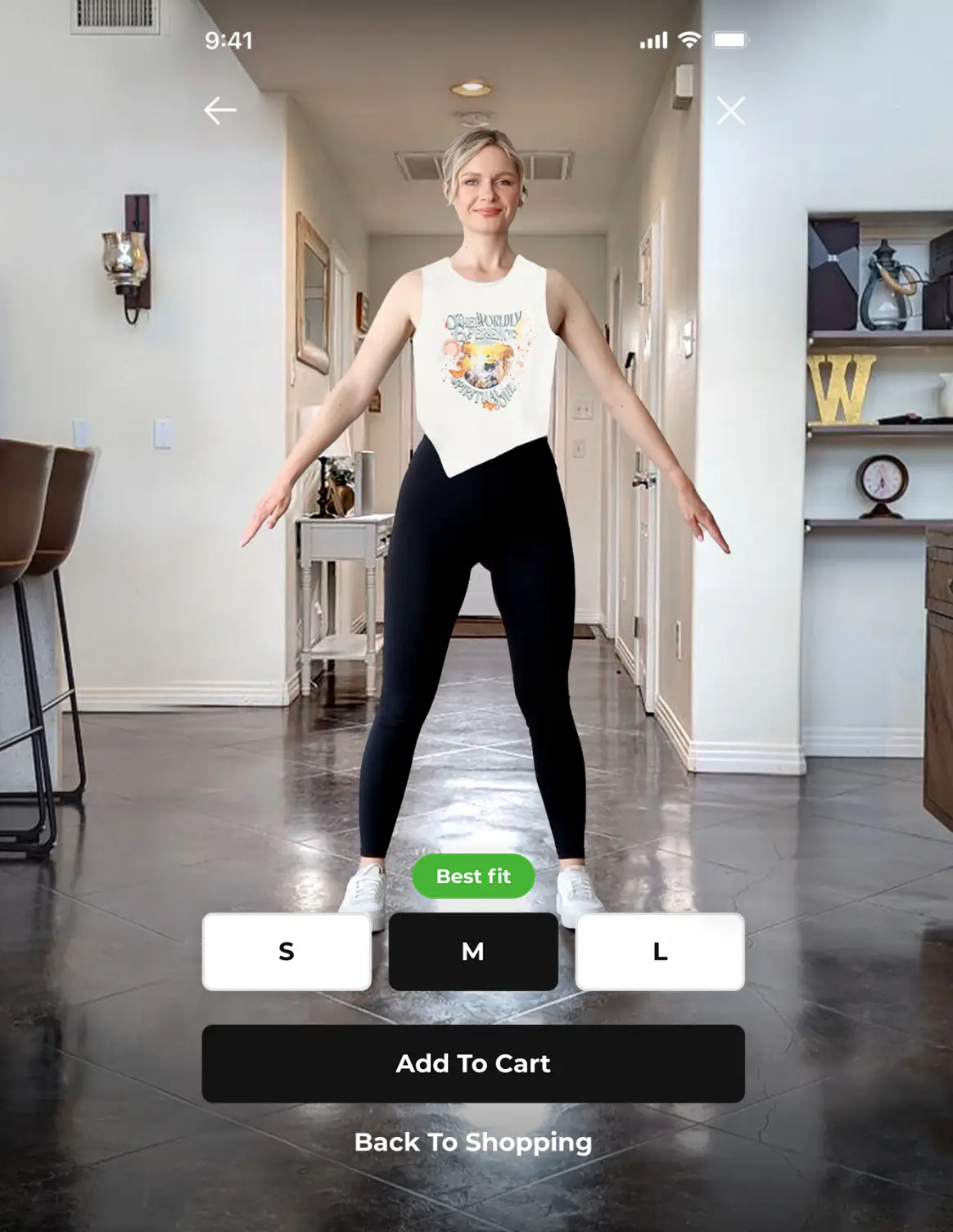

One of the most significant challenges in the fashion industry has been the inconsistency of sizes. Body scanning technology offers a solution by precisely measuring an individual’s body, ensuring that the clothing fits just right. This technology can drastically reduce the high return rates often seen in online shopping due to sizing issues. Additionally, body scanning offers a seamless and effortless experience, delivering accurate measurements for a perfect fit in just moments, without any inconvenience to the shopper.

Personalized shopping experiences

The adoption of 3D body scanning technology in the fashion industry marks a significant shift towards sustainability and digitization, catering to the diverse body shapes and preferences demanded by today’s consumers. By providing personalized fit solutions and reducing sizing issues, brands can significantly lower returns due to ill-fitting garments, enhancing customer satisfaction and fostering loyalty. Utilizing technologies like Mobile Tailor streamlines the measurement process, allowing for a more efficient production workflow that minimizes waste and aligns with consumer expectations for tailored, high-quality clothing.

Sign up for a 7-day trial of Mobile TailorEnhancing confidence

Fashion transcends mere attire, serving as a vital medium of self-expression and individual identity. Yet, the quest for garments that both resonate with personal style and fit well often leads to consumer frustration and insecurity.

A recent study highlights a significant challenge for the fashion industry: an overwhelming 56% return rate tops the charts across all e-commerce sectors. This underscores the urgent need for improved fit accuracy and alignment with consumer preferences.

Contributing to sustainable fashion

Body scanning technology holds immense potential to drive sustainability initiatives among consumers of the fashion industry, particularly Gen Z and Millennials who prioritize eco-friendly, ethical brands. By facilitating the creation of made-to-measure garments, body scanning technology helps reduce the environmental impact associated with mass production and excessive waste.

Today, many customers seek to buy clothing from brands that align with their values of social responsibility and combating climate change.

The future of body scanning technology in apparel

Looking ahead, the future of 3D body scanning in the fashion industry is poised for continued growth and innovation. Advancements in AI and 3D will further enhance the accuracy and efficiency of body scanning systems.

Moreover, the integration of 3D body scanning with augmented reality (AR) and virtual reality (VR) technologies will unlock new possibilities for immersive shopping experiences and digital fashion customization.

Mass customization in apparel will be the norm, not the exception. With the ability to quickly and accurately capture individual body measurements, clothing manufacturers can implement automated production processes that tailor garments to each customer’s specifications. More importantly, apparel customization will come hand in hand with low pricing. The wider application of 3D body scanning technology will make this solution more accessible for clothing manufacturers, helping them satisfy consumers’ desires for customized garments.

For instance, more clothing factories could be equipped with robotic sewing machines and receive orders directly from customers’ 3D body scan data. The machines would just cut and stitch fabric according to the precise measurements, producing custom-fit clothing at scale without the need for manual intervention.

Already a fleeting trend, virtual models, also known as digital avatars, will open up more possibilities for designers to experiment with styles, fabrics, and fits in a virtual environment, redefining the creativity of fashion campaigns. Additionally, designers will embrace more eco-friendly practices as the virtual models approach significantly reduces the time and resources required for traditional prototyping and sampling.

More and more brick-and-mortar fashion stores will implement web shopping solutions to present their cloth items in 3D on virtual mannequins. One current example is Outform’s Digital Mannequin, enabling customers to scan a QR code that allows them to view fashion items from various angles. The next step is making direct purchases via their mobile devices.

Final Thoughts

3D body scanning technology revolutionizes the fashion and apparel sector by providing exact measurements for custom-fit clothing. This innovation grants manufacturers access to detailed data on varying body shapes and sizes, enabling the creation of styles that suit diverse figures. It allows brands to produce precisely what’s needed, minimizing overproduction. Consumers benefit from clothing tailored to their unique measurements and preferences, eliminating the hassle of returns. This advancement represents a mutual benefit for both the industry and consumers, streamlining production, cutting down on waste, and ensuring high-quality outcomes.

As 3D body scanning technology advances and becomes more widely available, it’s set to reshape the fashion landscape, promising a future where clothing is crafted and purchased in fundamentally new ways.