MADE Outdoor is a ground-breaking online technical outdoor apparel company at the intersection of innovation, sustainability, and inclusivity. Co-founded by Cheryl LeBarr, a dynamic entrepreneur and outdoor enthusiast, the brand has garnered numerous accolades, including the ISPO Award 2022 and the OR Innovation Award 2023, for its efforts to make the outdoor industry more diverse and accessible.

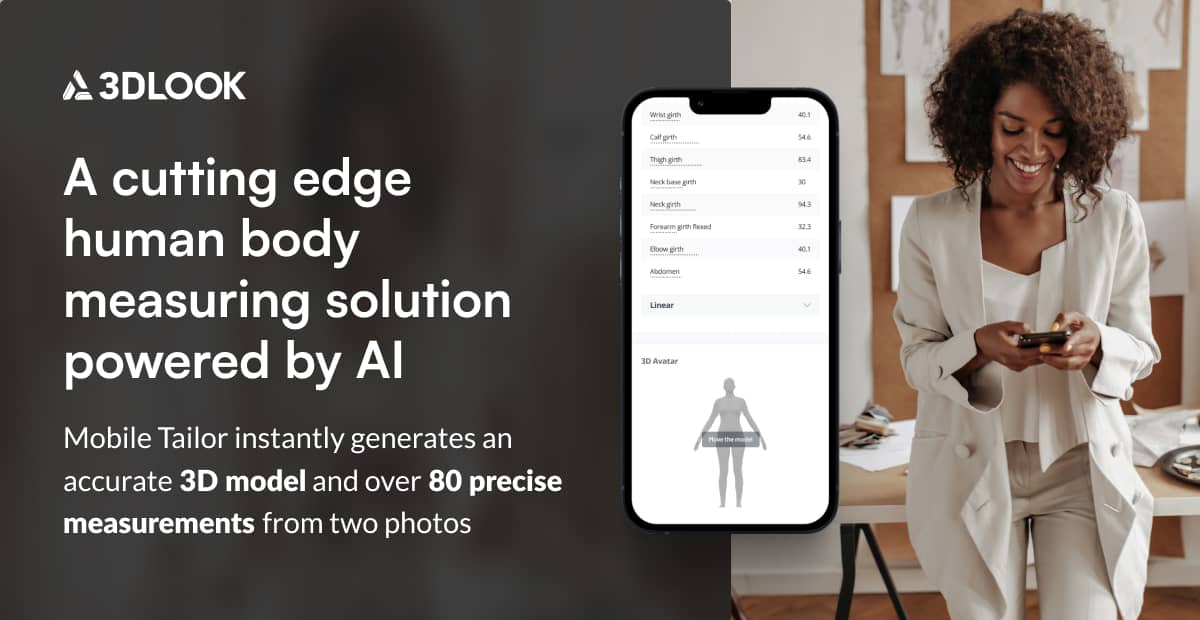

Through the brand’s pioneering use of 3DLOOK’s Mobile Tailor digital body scanning solution, MADE has not only achieved on-demand manufacturing at scale but has also drastically improved production efficiency and customer satisfaction.

The Challenge

MADE Outdoor faced early challenges with remakes and returns—primarily due to inaccurate sizing as it was lauching its brand in 2021. The brand needed to address these issues to realize Cheryl’s vision of creating an inclusive and efficient customer experience.

The Solution

MADE utilized 3DLOOK’s Mobile Tailor technology to refine its pattern design and fit in three distinct phases.

Data-Driven Approach: Phases of Transformation.

Phase 1: Crowdfunding to Large-Scale Size Run

Remake Percentage: ~14.6%

During this phase, MADE incorporated customer body data collected through 3D scanning to fine-tune the pattern fits. This acted as a large-scale size run, allowing the brand to create more personalized fits right from the get-go.

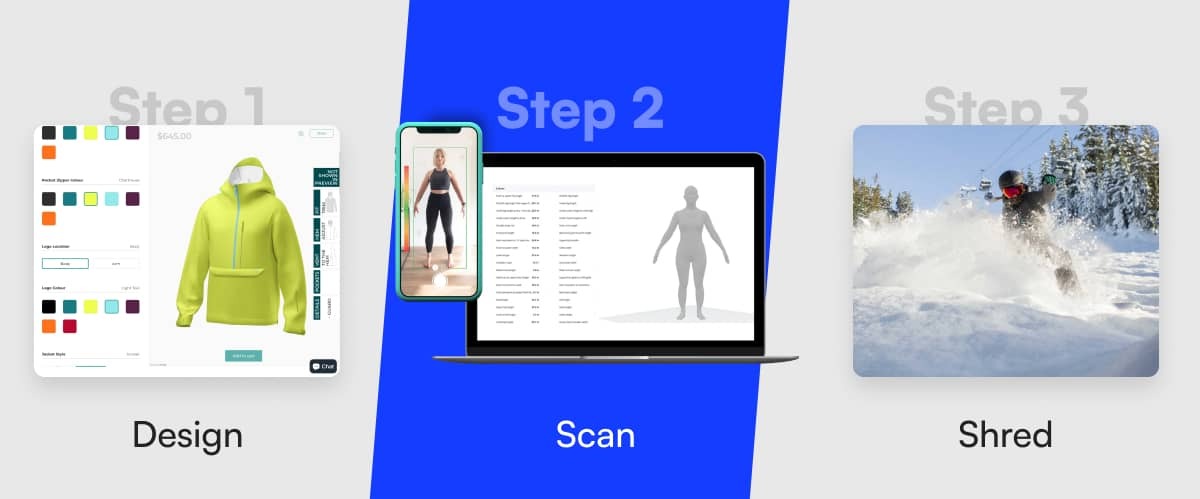

MADE Outdoor x 3DLOOK’s Mobile Tailor.

Three simple steps involved to get the best fitting and best performing gear.

Phase 2: Production 1

Remake Percentage: Further decreased to ~8.9%

The customer body data continued to be utilized for more accurate pattern adjustments, resulting in an even lower percentage of remakes.

Phase 3: Specialized Production

Remake Percentage: Reduced to an impressive 0%

The continuous use of 3DLOOK’s technology, combined with previous phases’ data, led to specialized patterns that eliminated the need for remakes altogether.

By taking a data-driven approach in these phases, MADE successfully leveraged technology to enhance efficiency in pattern design. This not only reduced the percentage of remakes but also enabled more personalized fits for a wide range of customers, contributing to the brand’s mission of inclusivity and sustainability.

Insights and Results

Why Mobile Tailor is a Game-Changer

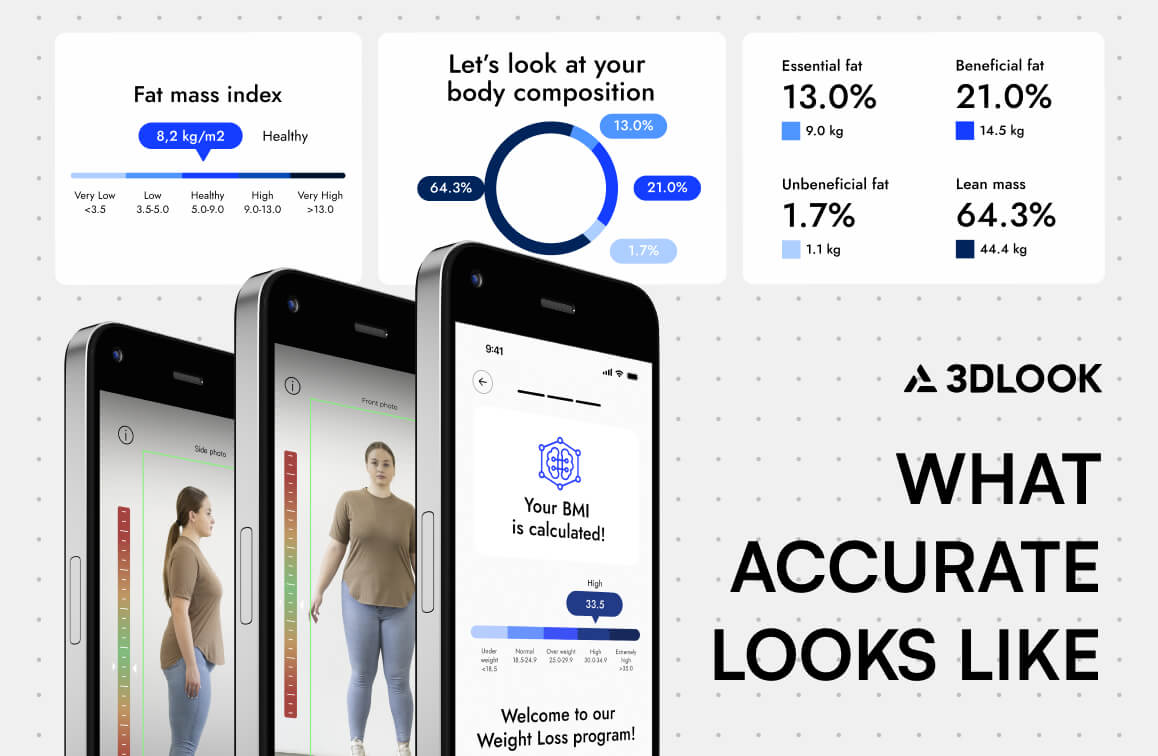

Increased Accuracy:

With Mobile Tailor, MADE achieved a remarkable production accuracy increase from an initial 85.4% to a perfect 100% in the latest phase. The technology was not only found to be more accurate than self-measurements but also served as a benchmark for validating self-measured data.

Consistency:

Mobile Tailor showed a 35%-77% increase in consistency compared to manual measurements. The solution also helped to pinpoint specific problem areas, such as bicep and rise, allowing Made to adjust patterns and reduce remakes.

Tailored Experiences:

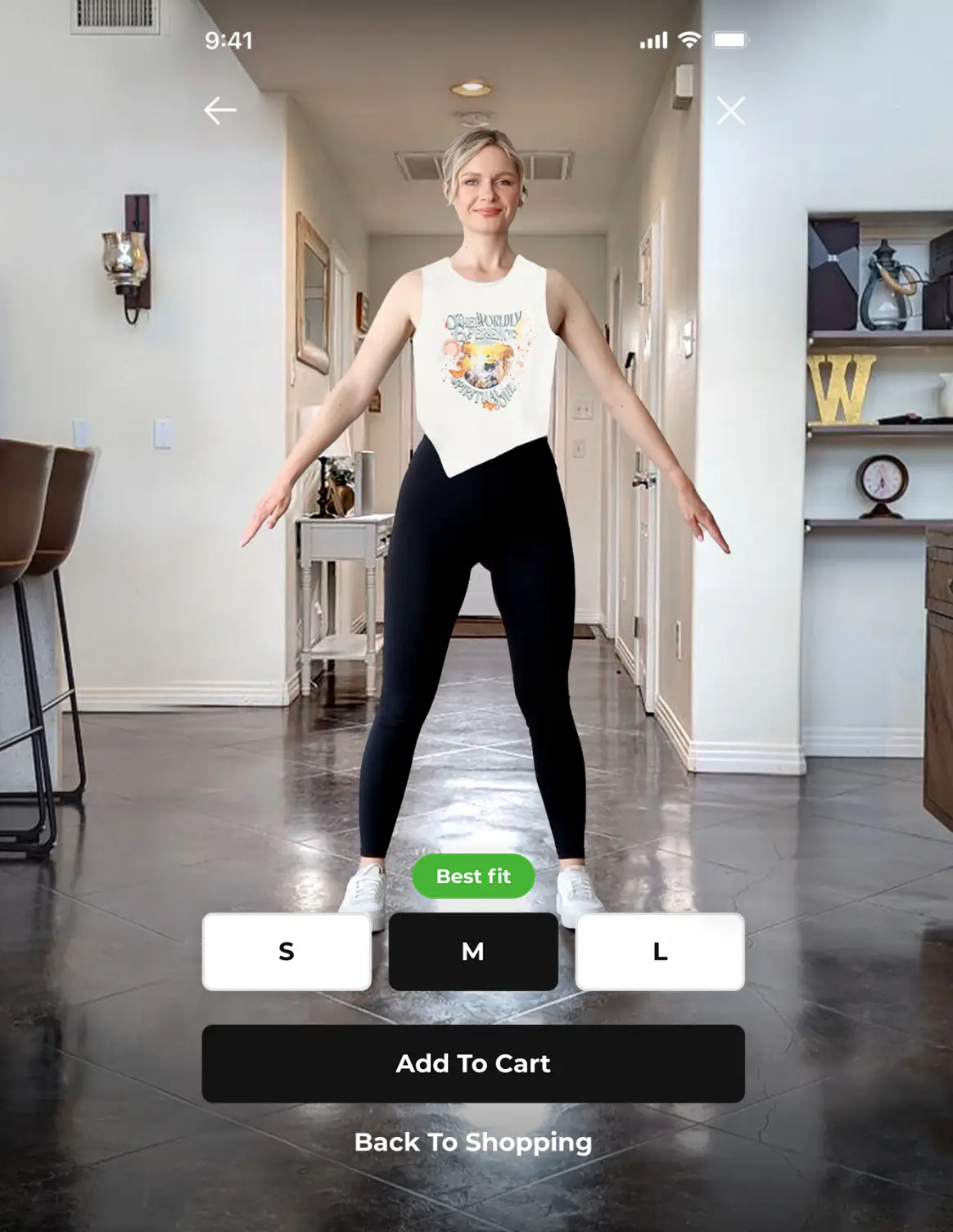

Using only 10 core measurements for most patterns, MADE plans to go in-depth for additional measurements for customers with unique sizing needs.

Efficiency:

With 3DLOOK’s latest accuracy update deployed in May 2023, no production units have needed remakes.

Testimonial

Cheryl emphasizes the importance of rethinking fit personalization and customer experience in technical apparel with 3DLOOK’s Mobile Tailor: “It came down to customer experience. It’s a conversion metric. We can sell more jackets online because people don’t have to measure themselves.”

What Makes Cheryl LeBarr and MADE Unique?

Cheryl’s unique journey from working at an outdoor shop in her hometown to becoming a Technical Apparel Instructor at the Wilson School of Design makes her an embodiment of the brand’s ethos. Her expertise and commitment to sustainability and inclusivity are not just business strategies but her life’s mission. This deeply personal connection fuels MADE’s commitment to innovation and sets it apart in the outdoor industry.

Conclusion and Future Outlook

In aligning technology with a visionary mission, MADE has transformed the landscape of technical outdoor apparel. Through 3DLOOK’s Mobile Tailor, they’ve achieved unparalleled efficiency and precision, drastically reducing remakes and elevating customer satisfaction. This harmonious integration of tech and purpose has not only revolutionized MADE’s operational dynamics but also raised the bar for what’s possible in the outdoor apparel industry.

If you’re looking to redefine how you approach technical outdoor apparel, there’s never been a better time to reach out to 3DLOOK. Become the next transformation story in an industry ripe for innovation.