Fashion is decisively moving away from one-size-fits-all mass production and toward creating custom apparel aligned with each person’s unique style and precise fit. There are technologies and notable companies powering a scaleable on-demand model. This comprehensive article will introduce you to them.

Moving beyond fast fashion’s one-size-fits-all approach, AI and 3D-powered made-to-order (MTO) and made-to-measure (MTM) systems offer a pivotal shift. They enhance retail by allowing personal fit and design choices through on-demand manufacturing.

Fashion Forward: Where Custom Choices Meet Perfect Fits The On-Demand Apparel Model Redefines Shopping Beyond Fast Fashion

In fashion, where preference and sizing issues commonly lead to dissatisfaction, the shift to on-demand systems is emerging as a solution ensuring choice, quality, and fit. These approaches, focusing on individual measurements and style preferences, allow brands to create a more personalized connection with their customers, enhancing loyalty and encouraging repeat engagements.

Shifting towards on-demand models not only caters to consumer preferences but also aligns with sustainability initiatives, significantly reducing waste and promoting eco-friendly manufacturing practices.

On-Demand Systems: A Necessary and Scalable Evolution in Fashion

On-demand systems are reshaping the fashion landscape, allowing consumers to customize their clothing with unparalleled precision. Leveraging advanced AI and 3D technologies, these platforms allow for a wide range of personalizations, from simple logo additions to automating fit adjustments. This level of customization ensures that each piece of clothing aligns perfectly with the wearer’s unique preferences, visualized in real-time for immediate feedback and adjustment.

Incorporating AI-powered mobile body scanning into the mix significantly enhances the accuracy of fit, fostering a more inclusive shopping experience and dramatically reducing the likelihood of returns. Furthermore, on-demand manufacturing systems streamline the production process, directly receiving precise data and digital assets that generate factory-ready files for automated manufacturing. This method drastically reduces waste by producing garments only as needed, marking a clear departure from the overproduction inherent in fast fashion and traditional retail models.

Addressing the apparel industry’s waste issue is a critical global challenge. The move towards on-demand systems marks a crucial, scalable shift towards sustainability, reflecting a needed evolution towards a more consumer-focused and environmentally responsible fashion sector.

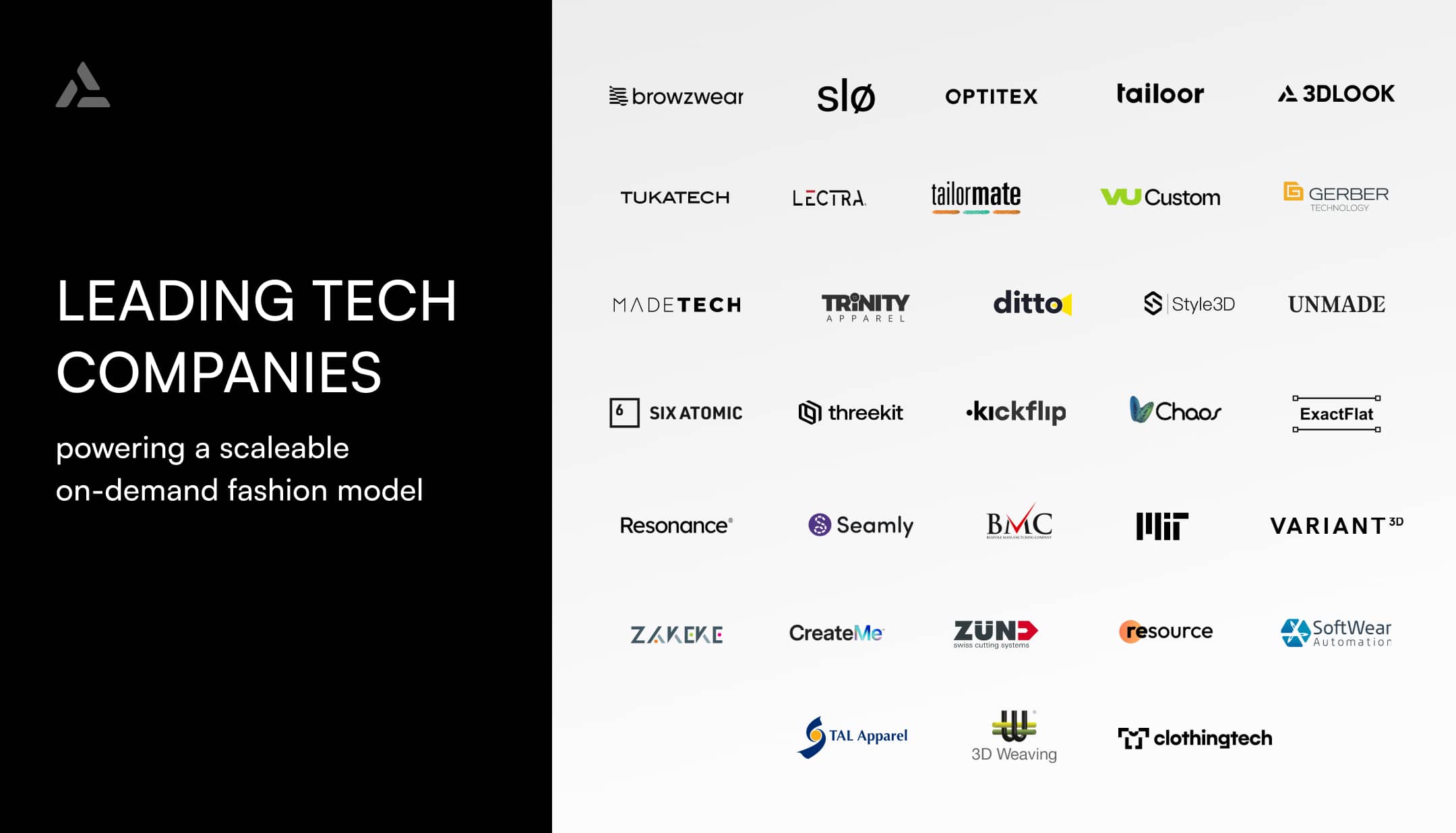

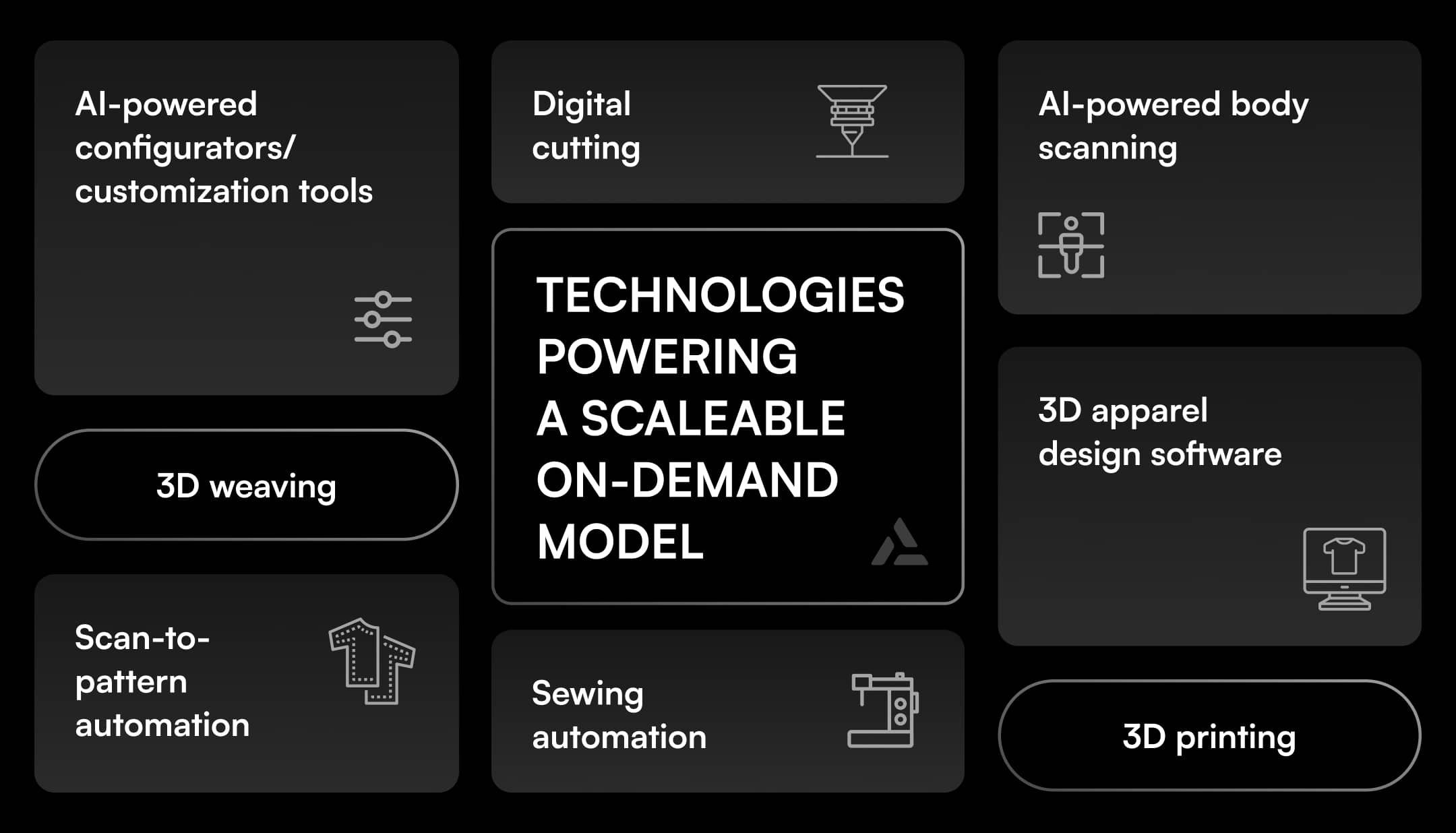

TECHNOLOGY OVERVIEW

Technologies Powering a Scaleable On-Demand Model

1. Empowering Custom Fashion with AI-powered Visual Commerce

The fashion industry is evolving, leveraging advanced fit technologies, 3D design, scan-to-pattern systems, and manufacturing automation, from order management to sewing. These innovations create a direct connection between creators, consumers, and manufacturers, enabling faster production of custom goods. This shift heralds a scalable, more sustainable, and efficient fashion ecosystem. Open platforms uniting top partners are crucial to this data and tech-driven, tailor-made future, accelerating the industry’s move towards innovation and precision.

These platforms combine advanced configuration capabilities with front-end 3D visualization tools enabling the design, sale, and creation of each garment individually, on demand, and at scale. 3D configurators typically cater to MTO models, allowing visual customizations. In contrast, more comprehensive systems support MTO and MTM models, automating everything from scan-to-pattern to order management systems, enabling scalability by delivering production-ready files to the factories.

While matching the growing consumer appetite for personalized fashion, AI-powered visual commerce platforms elevate the shopping experience and advocate for sustainability through decreased overproduction. The growth of these platforms signifies a pivotal move towards a fashion manufacturing landscape that is more focused on the consumer, efficiency, and sustainability.

KEY COMPANIES:

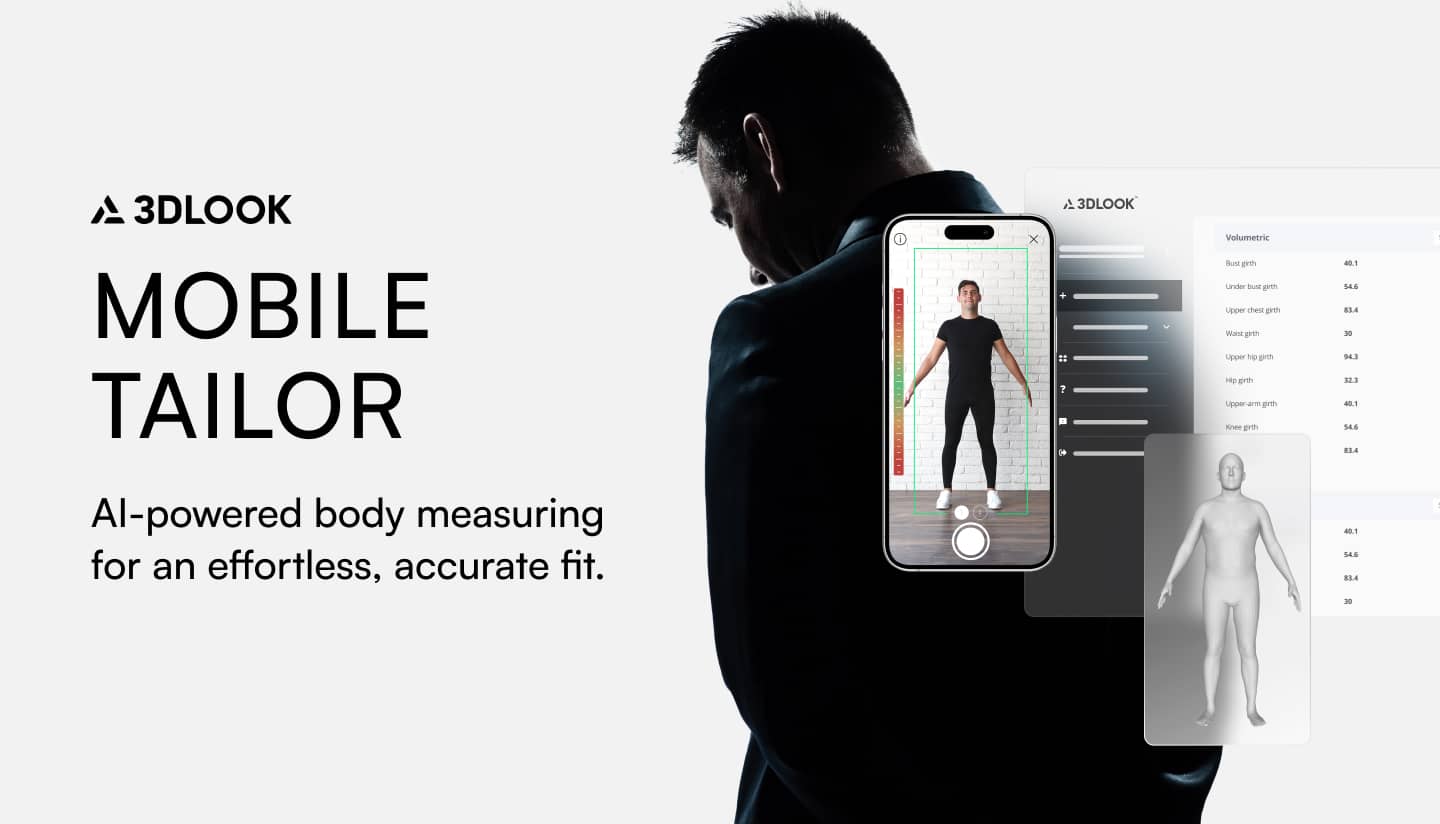

2. Next-Level Customization: AI Body Scanning and Automation

Mobile body scanning technology, such as 3DLOOK’s Mobile Tailor, is transforming traditional apparel manufacturing. Where traditional manufacturing models often inaccurately predict consumer demand, leading to overproduction and inventory waste, an on-demand model powered by mobile body scanning drastically reduces these issues. It provides precise, individualized sizing, eliminating the need for customers to order multiple sizes for fitting, thus cutting down on returns and overcoming inconsistent sizing standards.

This integration of AI body scanning with customization platforms enables precise body measurements, vital for scan-to-pattern automation and made-to-measure customization. Offering unparalleled personalization and fit, this approach signifies a move towards mass customization with a level of precision and customer satisfaction previously unattainable. Moving away from predictive manufacturing and standard sizing, mobile body scanning ushers in a more sustainable, efficient, and consumer-focused fashion era, establishing a new benchmark for industry personalization and waste reduction.

KEY COMPANIES:

3. Empowering Design with 3D Apparel Software

Pattern-making is pivotal in fashion design and garment production, acting as the bridge that transforms sketches into tangible garments. Traditionally, this process demanded considerable time and a specialized skill set, encompassing grading, marker planning, and fabric utilization. However, conventional methods need to catch up in speed, posing challenges for projects with tight deadlines and are prone to errors and inconsistencies due to their manual nature.

3D apparel design software, enhanced by Computer-Aided Design (CAD), revolutionizes this critical step.

By facilitating rapid prototyping and adjustments, these tools drastically reduce time-to-market and minimize waste from sample production. This integrated approach not only streamlines the design-to-production workflow, allowing for infinite design variations and precise tech packs, but also significantly improves the accuracy and consistency of patterns.

This leap in precision and efficiency is crucial for on-demand fashion, where quick turnaround and customization are essential. It marks a departure from traditional pattern-making to a more dynamic, error-reduced manufacturing process.

KEY COMPANIES:

4. Streamlining Fit with Scan-to-Pattern Automation

Scan-to-pattern automation revolutionizes apparel production by utilizing body scanning technologies to gather precise human measurements, far exceeding the capabilities of traditional manual methods.

These systems ensure that garments accurately fit a wide range of body shapes by algorithmically refining patterns to match body shape and measurement data extracted through body scanning, like 3DLOOK’s Mobile Tailor.

Beyond improving design precision and fit, these conversion systems have already demonstrated substantial savings in time and labor, underscoring their effectiveness in streamlining production processes.

As these platforms continue to develop, they promise scalable production solutions that reshape the fashion industry. This evolution signals a pivotal shift towards more sustainable practices and custom-fit garments, aligning perfectly with the on-demand fashion model’s goals.

KEY COMPANIES:

5. 3D Printing: A Catalyst for Sustainable Fashion Innovation

3D printing transforms the fashion industry, fostering intricate design creation and championing sustainability. This technology enables direct-to-fabric and direct-to-garment applications, revolutionizing how fashion is designed, produced, and consumed. By facilitating on-demand production without minimum order quantities, 3D printing ensures that only desired items are produced, from single pieces to short runs. This “smart production” approach eliminates overproduction, costly inventories, and the need for significant markdowns, aligning fashion production with environmental sustainability and economic efficiency.

Moreover, 3D printing’s versatility in fabric innovation and garment embellishment democratizes luxury fashion details, previously the domain of high-end designers. It empowers creatives to explore unlimited design possibilities and surface effects across diverse materials. By enabling personalized and small-batch production, 3D printing is reshaping the fashion landscape, offering a path toward more creative, sustainable, and consumer-responsive apparel manufacturing.

KEY COMPANIES:

6. 3D Weaving: Transforming Apparel Production

3D weaving technology is reshaping garment manufacturing by directly transforming yarn into complete garments, eliminating the conventional stages of fabric creation, cutting, and assembly.

This breakthrough reduces material waste and accelerates production from months to mere minutes, embodying a significant leap in manufacturing efficiency and sustainability.

Equipped with the ability to craft seamless fabric tubes from yarns while dynamically altering fabric shapes, 3D weaving machines introduce garments with unmatched strength, longevity, and design versatility. This method streamlines the production pipeline, facilitating the rapid scaling of on-demand woven apparel, a stark contrast to traditional manufacturing processes.

Differing from circular knitting, 3D weaving intertwines yarns at perpendicular angles, enhancing garment strength with fewer materials. This efficient, sturdy construction offers a sustainable alternative by using less yarn and generating minimal waste, aligning with environmental sustainability goals.

The advent of 3D weaving technology and its operational software disrupts conventional garment manufacturing, heralding a future where clothing production is faster, less resource-intensive, and closely aligned with evolving sustainability standards and regulations.

Moreover, 3D weaving technology is pivotal in empowering micro factories, enabling them to operate with unprecedented efficiency by producing garments rapidly and with minimal resource use, perfectly aligning with the agility and sustainability requirements of modern manufacturing.

KEY COMPANIES:

7. Evolving Digital Cutting: Enabling On-Demand Fashion with Integrated Systems

Digital cutting is evolving alongside the demand for personalized, on-demand fashion. Automated systems and single-ply cutters lead this shift by enhancing precision and integrating seamlessly with fashion cycles, reducing fabric and labor costs.

The shift to single-ply cutting underscores this evolution, streamlining production from fabric roll to cut piece. This method is essential for on-demand fashion, efficiently accommodating custom and single-piece orders. Its integration with production workflows offers unparalleled flexibility and speed, responding quickly to consumer preferences with minimal waste.

AI’s pivotal role in advancing these systems is automating textile scanning and cutting to optimize fabric use and accelerate production. This integration boosts efficiency and sustainability, reducing waste and energy use. Digital cutting technologies enhanced by AI mark a significant step towards a sustainable, efficient, and consumer-centric fashion industry, reflecting a commitment to dynamic, on-demand apparel manufacturing.

KEY COMPANIES:

8. Redefining Apparel Manufacturing with Sewing Automation

Sewing automation marks the final frontier in fully automated apparel manufacturing, steering the industry toward on-demand, small-batch, and made-to-measure production. Enabled by advancements in robotics and AI, sewing automation can optimize patterns and adjust to various fabrics. It tackles key challenges such as rising labor costs and shortages of skilled workers. Automating the intricate sewing process will streamline the production chain from custom design to the final perfectly fitted garment, lessening reliance on low-wage labor and diminishing the environmental toll of extensive supply chains.

Automated sewing systems provide a viable solution to these challenges, offering substantial labor cost savings and addressing the scarcity of skilled labor. Capable of matching the output of several artisans, sewing automation facilitates a return to regional production in higher-wage locales, significantly curtailing production times and delivery distances. This shift enhances the industry’s agility in trend response and slashes CO2 emissions, laying the groundwork for a sustainable and economically sound fashion manufacturing future.

While current technologies focus on simpler garments like T-shirts, the potential for massive evolution exists, promising tailor-made production at scale and heralding a future of innovation in apparel manufacturing.

KEY COMPANIES:

9. On-Demand Factories: Pioneering Sustainable Fashion Manufacturing

On-demand factories, or micro-factories, represent a transformative shift in apparel production. They focus on small batch production, low MOQ, and personalized, one-off garments through advanced AI and 3D tech-enabled operations. This innovative approach addresses the inefficiencies of traditional mass production by eliminating excess inventory and reducing waste, aligning closely with real-time consumer demand and trends. By adopting this model, brands can significantly alter their supply chains, moving towards a more sustainable and economically viable manufacturing process that minimizes environmental impact and aligns with sustainability goals.

Strategically located closer to consumers, micro-factories reduce the carbon emissions associated with extensive logistics and double as efficient distribution centers. This model enables brands to drastically shorten production cycles and deliver customized products directly to consumers, facilitating small-batch manufacturing and mass customization. The proximity to the market ensures a quicker response to consumer preferences, enhancing brand agility and customer satisfaction while promoting a shift towards environmentally responsible production practices.

The integration and collaboration of advanced technologies needed to enable mass customization—from body scanning technologies like 3DLOOK’s Mobile Tailor to automated sewing—are already making on-demand factories a reality, underscoring the necessity for a cohesive ecosystem to enable scalability. This synergy is essential for making on-demand production cost-effective, ensuring a favorable return on investment for brands. As these technologies continue to work in tandem, they pave the way for the expansion of micro-factories, embodying a future where sustainable, on-demand fashion manufacturing is not just possible but practical for brands looking to innovate and reduce their ecological footprint.

KEY COMPANIES:

- Unspun/Vega

- slø

- BMC Fashion

- RESOURCE Fashion

- Resonance

- Trinity Apparel Group

- SoftWear Automation

- TAL Apparel

- CreateMe

Final Thoughts

As we advance into 2024, the fashion industry is being transformed by on-demand technologies, leveraging AI and 3D innovations to meet individual style preferences and promote sustainability. This shift from mass production to technology-driven, made-to-order models is reducing waste significantly by ensuring that apparel fits perfectly, thereby decreasing returns and excess production.

The move towards on-demand fashion is not merely a trend but a necessary adaptation to the increasing consumer demand for personalization and ecological responsibility. Technologies like digital cutting and AI body scanning are making these changes scalable and sustainable, setting new industry standards for innovation and environmental care.

In summary, the on-demand fashion industry of 2024 is at a pivotal juncture. With cutting-edge technology, it is paving the way for a future where fashion is not only customized to individual needs but also aligned with global sustainability goals. This evolution is poised to influence broader manufacturing practices, championing a shift towards more responsible production across industries.